Could any of us have imagined back in the early 2000s that we'd be so close to the magic of smart houses, smart cars, innovative centers, and first-class automated services? Nevertheless, today, the world's population is increasingly engaged with an intelligent discipline called Smart Manufacturing (SM).

What is Smart Manufacturing? It is not merely a concept but a big family of technologies that bring new opportunities and enhanced efficiency to the manufacturing domain—and, in turn, to the entire supply chain.

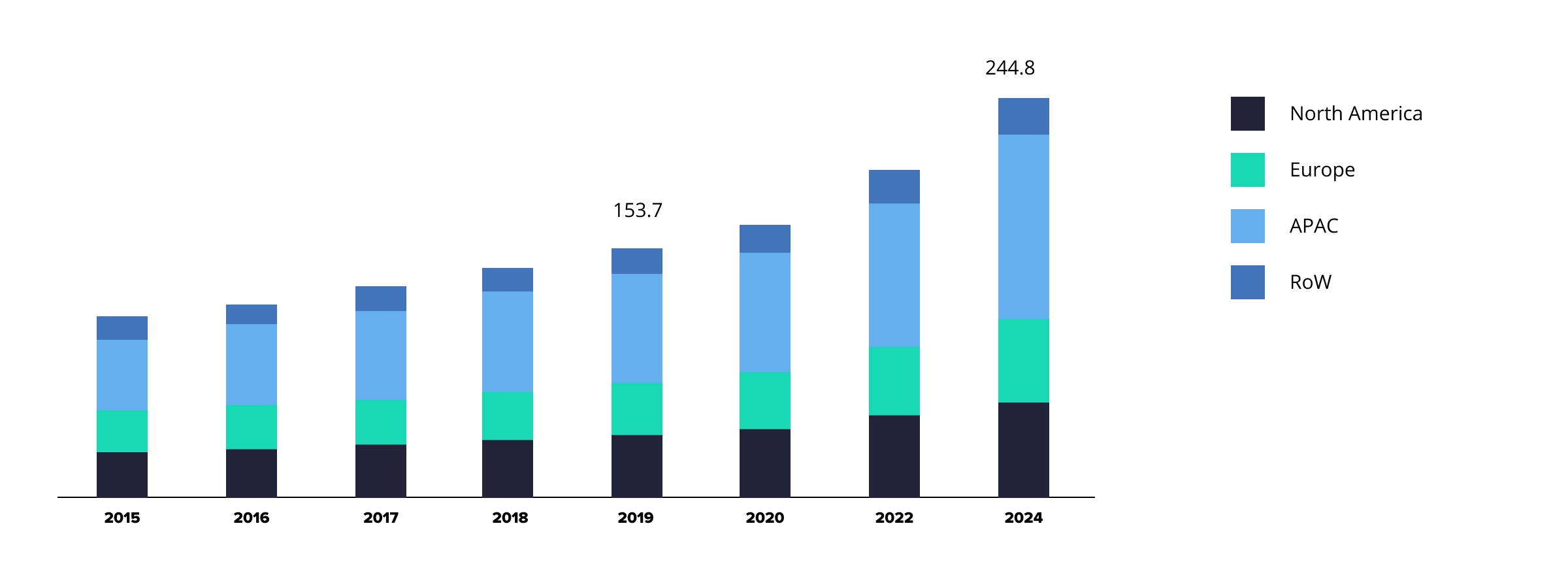

A Market-and-Market report valued the smart factory market at $154B in 2019, growing at a CAGR of 9.8% during 2019–2024. Its growth is propelled by the evolution of the Internet of Things (IoT), the population of enabling technologies in manufacturing, rising adoption of industrial robots in the sector, and connected enterprise, along with mass production to cater to increasing population needs and demands.

SoftServe has observed a considerable increase in the manufacturing business sector's growth, with APAC being the largest region, followed by EMEA and North America. Manufacturers are looking for ready-made solutions, not custom development. Each wants to become smarter, better, and more innovative to keep up with fast-paced SM market development. They're also seeking to understand where they are within their Industry 4.0 digital journey to create a solid digital roadmap supported by a business case.

The Covid-19 Phenomenon

The business ecosystem is changing rapidly, and the smart manufacturing core model is undergoing modifications. In light of recent crucial developments shaping the world, we can clearly define the Covid-19 phenomenon as connected to domain development. Why do we call it a phenomenon?

Covid-19 as Business Challenge

Let's be fair. The pandemic severely disrupted the plans of the leading manufacturers. It demonstrated a heavy impact on handling things quickly and efficiently, such as demand drops, supply interruptions, market uncertainties, and cost increases. According to Deloitte, since early 2020, manufacturers have experienced significant disruptions starting with demand/supply imbalances and regional work stoppages.

Covid-19 as Business Accelerator

At the same time, we currently witness an even more active SM investment trend. The world of business has become well aware that only by being flexible, innovative, and using the latest digital solutions to the fullest can they stay competitive and win. According to a recent McKinsey & Company survey, approximately 93% of manufacturing and supply-chain professionals plan to focus on their supply chain's resilience, while 90% plan to invest in digitization talent.

How can they turn their plans into action? This can be done with the following market enablers:

- Artificial intelligence

- Blockchain in manufacturing

- Industrial Internet of Things (IIoT)

- Robotics

- Cybersecurity

Looking closer, we see that these enablers are about data: either generation, acceptance, or both. Data operations help to make the process of production more efficient, transparent, and flexible. It is why most companies choose to invest and explore the benefits.

Smart Manufacturing Transition: Advantages & Challenges

"Smart" factories are aimed at mass production while, at the same time, maintaining maximum flexibility. It is ensured by an elevated level of automation and robotics of the enterprise. Automated control systems for technological and production processes are widely used. IIoT technologies provide machine-to-machine interoperability of equipment. The enterprise's production assets, equipped with sensors and communication operating on the IPv6 protocol, can produce products often without human intervention. Big Data technologies allow us to cope with sharply increased information flows from sensors and automated control systems.

Logically, there is an abundance of advantages to consider:

- Faster response to market needs

- Data-driven decisions

- Improved margins

- New revenue streams

- Long-term market presence

Any Challenges? Definitely.

The transition to smart manufacturing is a highly complex task of implementing digital programming. Research by McKinsey Company indicates that about 70% of SM initiatives fail to achieve their stated objectives. Their 2019 survey found that after starting Industry 4.0 journeys, most companies remain stuck in a pilot trap: only 44% were conducting site-wide implementation. Only 38% were looking at horizontal integration beyond the four walls of the factory.

It sounds threatening and calls for an urgent solution. What can be done about it?

To address the challenge, manufacturing organizations need a solid and experienced partner to support the entire transformation journey—from strategy to execution. Often, a consulting partner can offer a solution but lacks the expertise to make it work in practice. Or a tech partner who specializes in implementation but can't help with much else. A business needs a partner which provides a holistic picture of the detailed strategic plan and the subsequent execution.

Why SoftServe?

SoftServe fits this prerequisite. We are a digital authority that advises and provides at the cutting-edge of technology. SoftServe reveals → transforms → accelerates → optimizes how tech companies and enterprises do business.

As a premier digital partner for dozens of Fortune 500 enterprises, SoftServe has deep expertise in manufacturing. We've developed and implemented solutions for the following domains:

- Fast Moving Consumer Goods (FMCG)

- Agriculture

- Healthcare and Pharma

- Logistics and Transportation

- Energy and Heavy Manufacturing

- Discrete and Process Manufacturing

- Apparel and Fashion

- Retail

Companies have an urgent need to expand production in the current fiercely competitive environment. They must increase margins and optimize resources. Manufacturers must utilize equipment as efficiently as possible, minimize the risk of downtime, and automate monitoring and tracking processes at all stages. And all this while keeping costs down. SoftServe can give you a hand with that. Here's a sample of our track record:

- 25+ years of developing and commercializing software solutions.

- 15+ years of experience in the design and implementation of IoT solutions and embedded systems.

- An IoT core team of over 10 people ready to consult, design, and deliver IoT solutions.

- 6,500+ engineers ready to implement software solutions.

What We Offer:

- Business Applications. We deliver valuable solutions powered by market-proven design thinking, service design, and product management methodologies.

- Advanced Analytics. Based on your digital transformation journey, we support you in handling Big Data and leveraging machine learning efficiently. Our approach reveals valuable data insights and equips business units with real-time analytics and proactive decision-making.

- IoT Cloud and Platforms. Centralized data is needed to accumulate, systemize and leverage collected data. We design reliable data storages using market-proven solutions from industry leaders such as AWS IoT, Azure IoT, and Google IoT Suite.

- Embedded Software. We deliver software for IoT and connected devices, conforming to safety, reliability, and power consumption requirements.

- Hardware Design and Prototyping. We can help choose the best available technology on the market for individual business needs and demands or customize existing solutions.

Responding to change: today and in the future

Manufacturing expectations are constantly growing. To maintain smooth operation during peak periods and to adapt to rapidly changing market trends, they must be as flexible and efficient as possible. This can only be achieved by optimizing resources. It is about creating an optimal long-term infrastructure that will allow you to respond to changing production requirements and provide rational instructions and analysis of work processes quickly.

The growth potential of the SM world market is enormous. Your business needs an experienced advisory and execution partner to stand up to the competition and use SM's potential to the fullest.

Let’s talk about how SoftServe can help you capture this market and align with your business needs, values, and demands.