Don't want to miss a thing?

Improve Corrosion Management And Ensure Asset Integrity With Computer Vision And Machine Learning

The oil and gas sector is challenged with coating breakdown and corrosion detection across the entire asset management lifecycle. Energy companies lose billions of dollars annually due to damage caused by ineffective asset integrity management. Oil and gas industry leaders can mitigate the problem by moving from reactive to proactive asset maintenance to prevent asset failure and downtime, lower maintenance costs, and ensure employee and environmental safety.

Discover how to apply advanced technologies to proactively monitor for corrosion, screen for anomalies, and detect additional defects.

The Pinnacle Success Story

Our client, Pinnacle, is a leader in developing data-driven solutions for the oil and gas, chemical, mining, and water and wastewater industries. The company helps industrial facilities better leverage their data to ensure increased production, optimized maintenance spending, and improvements in process safety and environmental impact.

Pinnacle is focused on helping its customers manage risks, optimize costs, and ensure compliance through its Data-Driven Reliability framework. This framework consists of four categories: data collection, organization, intelligence, and strategic decisions. Pinnacle’s Research and Development team continues to invest in the intelligence segment of this framework, specifically through Quantitative Reliability Optimization (QRO), to deliver data-driven insights for its clients.

Data collection and organization are among Pinnacle's strong points, and their clients can confidently make strategic decisions. However, they wanted to further help their customers create robust data reliability programs.

Pinnacle wanted to embrace cutting-edge technology and directly link data collection and intelligence segments in one solution. Recognizing they needed edge technology expertise, Pinnacle reached out to SoftServe. SoftServe was asked to prove the feasibility and validate the business value of a computer-vision based approach for detecting and classifying coating anomalies and corrosion using visual data.

Our Approach

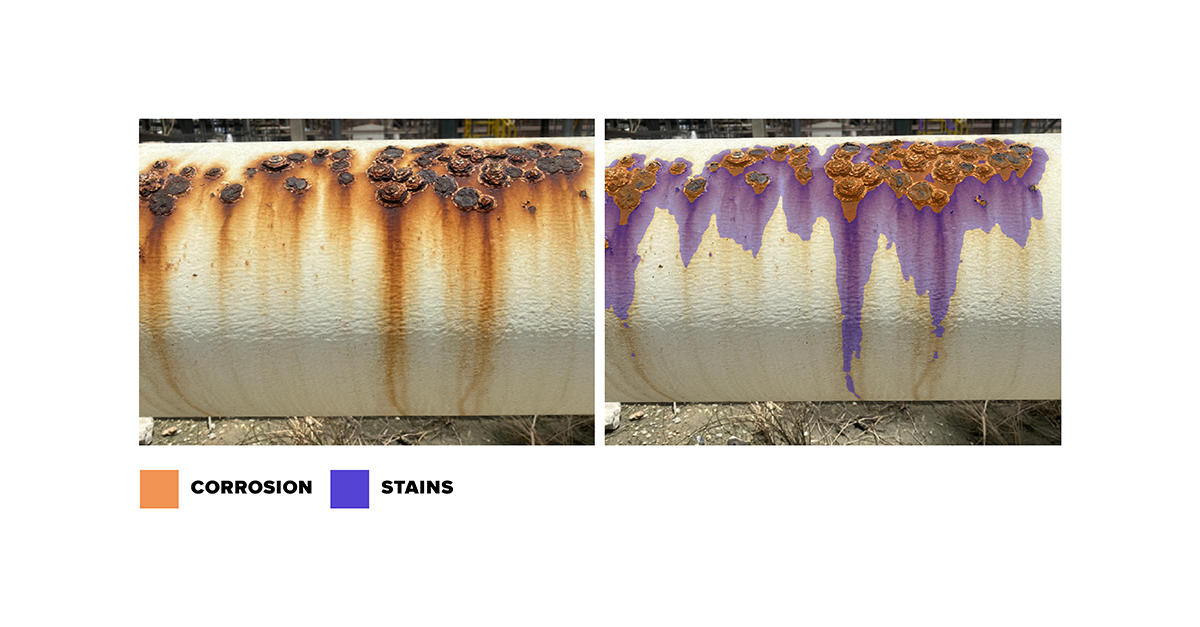

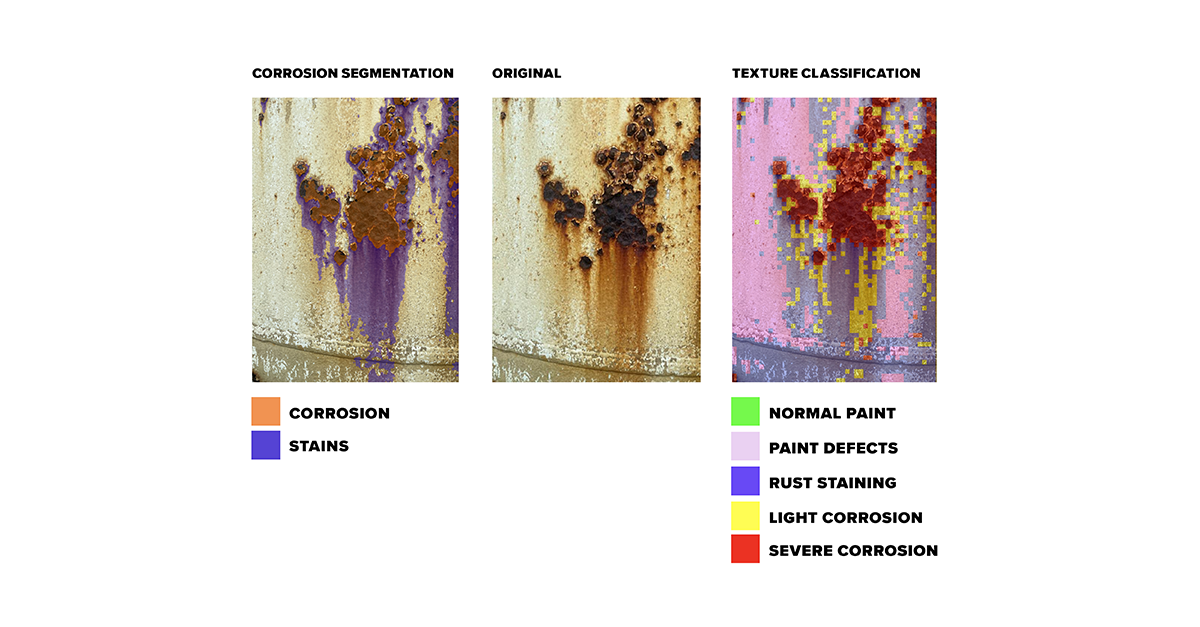

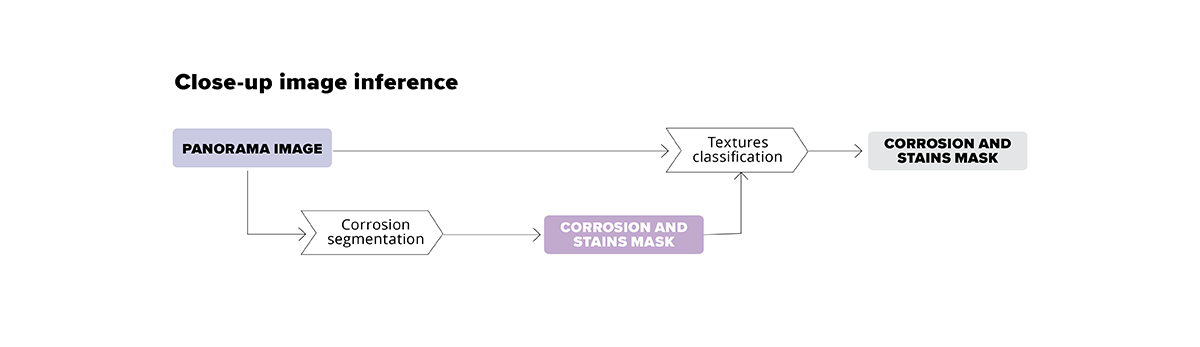

SoftServe’s experts helped Pinnacle develop effective ML models for corrosion segmentation and texture classification. The final model can generate coating breakdown and corrosion maps, evaluate damaged areas, and mark corrosion damage according to a few severity classes.

"This was phenomenal work, SoftServe. I believed in you after the first phase, but I didn't know if you had bit off more than you could chew with the second phase, and you delivered. Very well done," - Mauricio Olivares, Chief Operating Officer, Pinnacle Reliability.

We conducted several experiments to examine the problem from a different angle to help determine the best solution for the client. We tried using open-source data and a classifier based on embedding vectors, but the metrics were worse. Since there aren’t many open-source textural datasets, we decided to gather our own big datasets with specific textures.

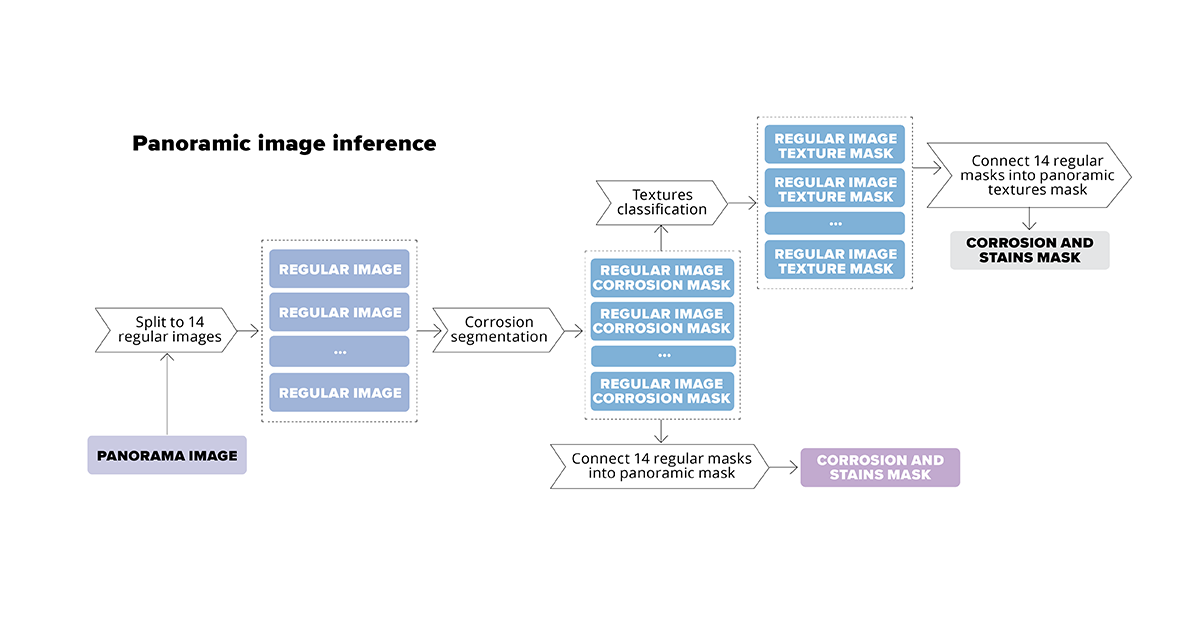

Pinnacle provided panoramic images converted to a 2D view suitable for labeling purposes. SoftServe’s experts, in collaboration with the Pinnacle team, conducted the labeling workshop and developed image analytics to evaluate distribution, calculate statistics of coating damage and corrosion, etc. The labels for the datasets were:

- Corrosion segmentation: corrosion and stains.

- Texture classification: severe corrosion, light corrosion, paint defects, rust staining, and normal paint.

We split the dataset of images into three parts: training, validation, and testing for both corrosion segmentation and texture classification.

The texture classification solution uses the sliding window approach and classifies the crops of an image with the size of 128 px x 128px. This size showed the best result in our previous experiments compared to other tested sizes. During experiments with the supervised and unsupervised classification of the textures, we tested the most popular machine learning algorithms, such as XGBoost, K-NN, Centroid-based, SVC, plus others. We decided to use ResNet18 as a final model for texture classification because it gave the best data results.

For corrosion segmentation, we tested several fully convolutional networks with the UNet-like architectures. During the hyperparameter tuning process, we tested several parameters of the segmentation pipeline such as model architecture, model encoder, loss function, number of epochs, batch size, input size, and image input method. This allowed us to find the optimal configuration of the pipeline. In the final implementation, we used the PSPNet architecture and an EfficientNet encoder.

Solution Outcomes

Together with Pinnacle, the SoftServe team successfully completed the following project deliverables:

- Corrosion Segmentation ML model. Detects corrosion and rust stains on images of the facilities taken by a panoramic handheld camera.

- Texture Classification ML model. Detects paint defects, rust staining, light, and severe corrosion on close-up images of the stationary equipment.

- Datasets. Annotated sets of panoramic and close-up images used to train ML models containing labeled data in different categories.

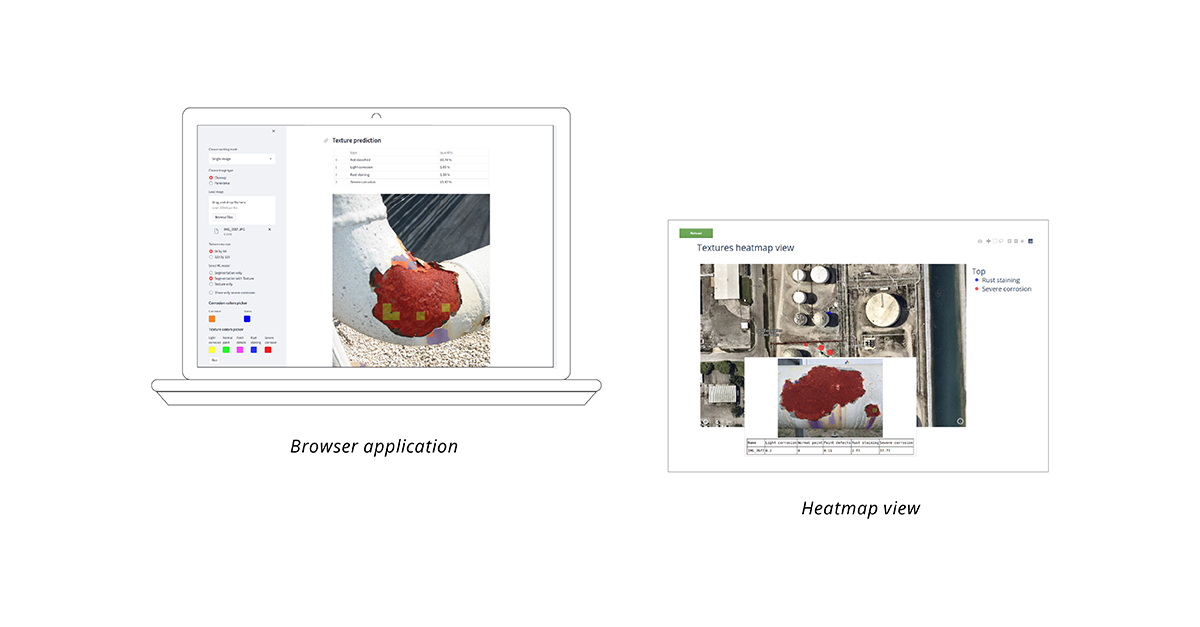

- User Interface. A simple browser application hosted on the secured VM allowing a user to tune processing parameters, run ML models in real time on the selected images, and see the big picture on the map. The UI allows the user to process images one by one with a preview or a batch processing of the entire directory passed as a parameter.

- Technical Report. Outlines the chosen approaches and techniques for building the pipeline and incorporates the results of the main experiments with the provided conclusions and potential improvements for future development.

Value Delivered

SoftServe helped Pinnacle enable its customer to move to a more proactive asset maintenance approach and, in doing so, delivered these additional benefits:

- Automation of corrosion detection with the help of deep learning models.

- Moving to data-driven decision making.

- Classifying corrosion and other defects on assets using visual data taken by the existing equipment as the solution doesn’t require purchasing additional expensive devices.

- Ensuring more effective planning of inspection operations.

- Proving the solution viability to stakeholders to minimize risks and accurately plan the budget.

- Designing a PoC that proved the solution’s value to the client and verified it could be brought to market faster as either an extension of existing products or standalone.

LET’S TALK about how SoftServe can help you connect data to business decisions and make asset integrity management more efficient by leveraging computer-vision and machine learning.