Don't want to miss a thing?

Digital Twins and the Industrial Metaverse

In an ongoing series about the digital twin, this article explores the role of the industrial metaverse and digital twins.

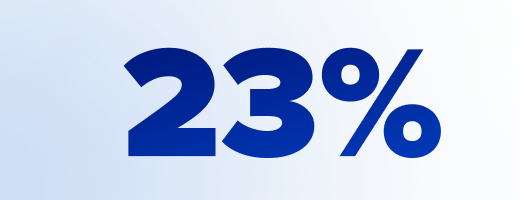

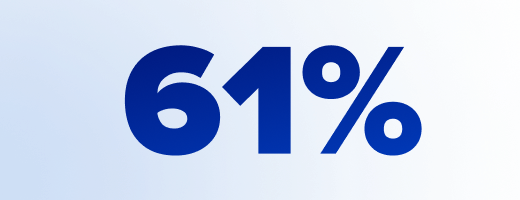

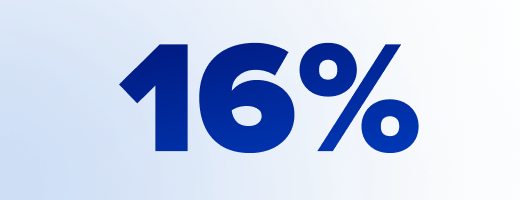

More organizations and their leaders consider the industrial metaverse and digital twins the next destination on their digital journey. Analyzing inquiries from various organizations, SoftServe sees the following distribution of requests about the industrial metaverse and digital twins:

of requestors are at a reveal stage, where they still learn about the possibilities of the industrial metaverse and digital twins and the business value they bring.

are at the transform stage, where they already define a business case and seek advisory consultations and support to validate their idea, solution design, and technology evaluation.

of requests are at the implementation stage and look for a particular expertise in robotics, extended reality (XR)/virtual reality (VR), artificial intelligence (AI)/machine learning (ML), and internet of things (IoT) to accelerate development.

Two types of metaverse

For making distinctions, please make sure everyone involved in your digital initiatives is aware of the difference between the industrial metaverse and consumer metaverse.

As you will see, the industrial metaverse and consumer metaverse have different business goals and cover different business areas.

The industrial metaverse is an industrial environment like a production line, mining site, equipment, or factory facility. Environments where your engineers, operators, and supervisors interact. The industrial metaverse intends to increase efficiency and reduce operational costs.

The consumer metaverse is a virtual environment where your consumers visit a virtual store or bank to, for example, speak to a virtual assistant. The consumer metaverse is intended to improve your customer experience and loyalty, increase sales, and generate new revenue streams.

As you prepare for your digital journey, this article only focuses on the industrial metaverse and explains how it’s connected to digital twins through foundational aspects.

Business motivation

Let’s take a closer look at how different businesses benefit from the industrial metaverse and digital twins. The most representative examples across business domains are automotive, manufacturing, mining, and oil and gas.

Automotive

Collaborative car design in the virtual environment, including testing of individual parts and virtually integrating them, significantly accelerates time to market and reduces the costs of car design and engineering. Like car design, the industrial metaverse also quickens factory design, whereby you virtually design a factory layout, simulate how humans and robots interact on the assembly line, and simulate a production launch of a new product to evaluate potential damage during manufacturing and assembly before assemblage in a real factory.

Manufacturing

Like automotive, the industrial metaverse lowers the cost of product and factory design. In addition, digital twins of the production line predict failures, optimize energy consumption, or simulate CO2 emissions for different manufacturing scenarios. Business value and application scenarios vary for discrete and process manufacturing.

The automotive and manufacturing use cases above cover design and engineering steps in the value chain. The industrial metaverse and digital twins help you simulate different scenarios in a virtual environment. Then, you apply what you learned in a real environment, with less intrusion and expense.

Mining

The metaverse of a mining site — a 3D model of the entire mining site — enables intuitive and real-time navigation through all segments of the site. You also use 3D models to figure out road slopes and perform various computations, considering road and weather conditions and traffic, for example, to optimize routes for the tracks running within the mining site and deliver real-time recommendations to drivers.

Oil and gas

Digital twins increase production and reduce energy consumption. Your data scientists create a model for you that calculates which equipment configuration provides the better outcome based on statistical methods, data science, and computational optimization.

The mining and oil and gas use cases cover production and operations. In these cases, the industrial metaverse and digital twins boost real-time awareness and supply solutions to increase operational efficiency.

Additionally, bolstered common goals include:

- Decision-making support

- Quality improvement

- Safety and sustainability enhancements

- Lower costs for design, operations, and maintenance

All the benefits can be graphically summarized as follows:

|

|

|

|

|

Decision-making support |

Increase efficiency & effectiveness |

Increase awareness & collaboration |

Reduce design, operations, and maintenance costs |

|

|

|

Improve safety & sustainability |

Improve quality |

While this gives you an idea of what your business gets in return from investing in the industrial metaverse and digital twins, the first step in your digital journey is to evaluate the business value.

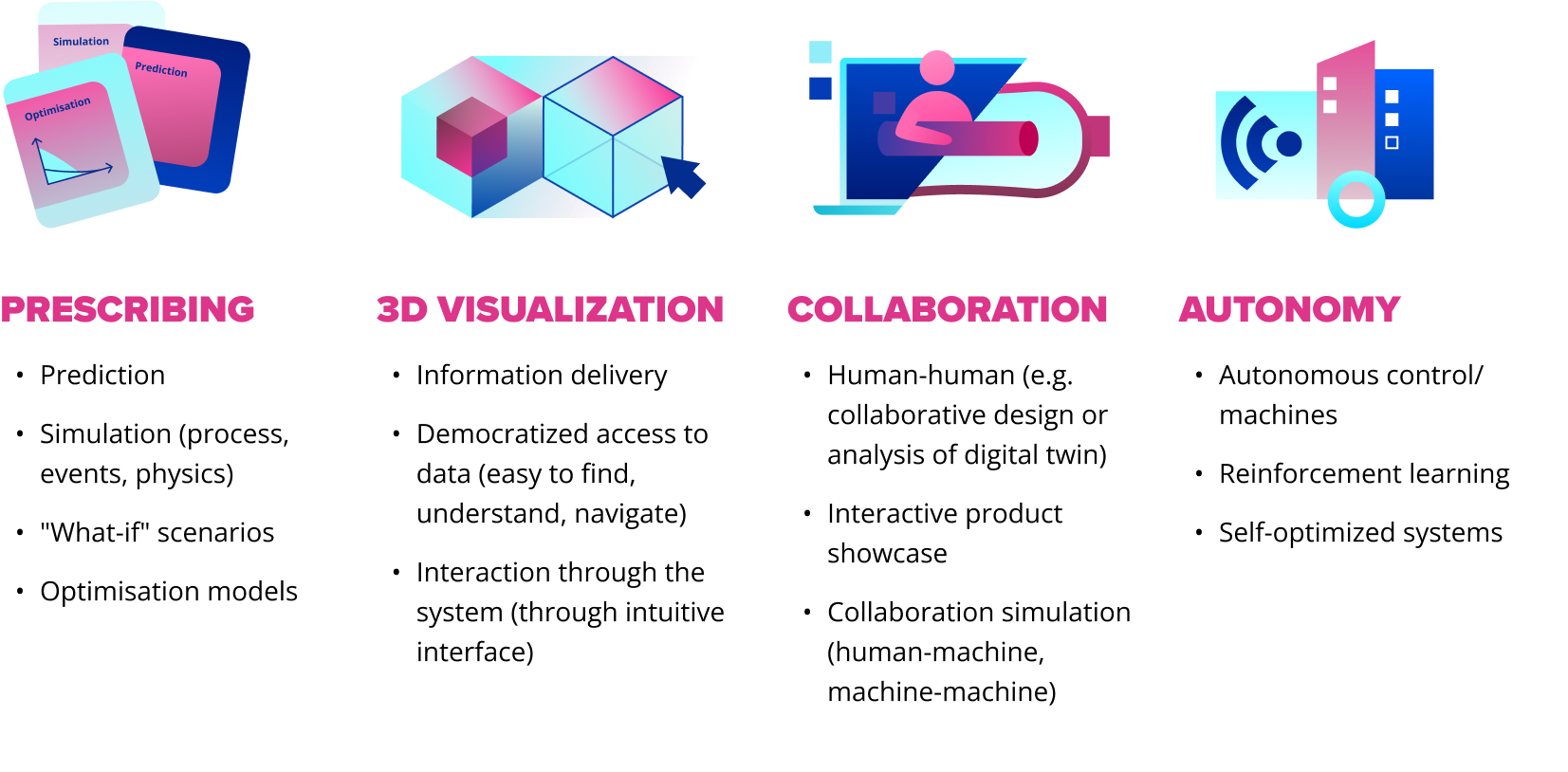

Four application scenarios

For tech-savvy business leaders, who want to build good sense and an intuition about what the industrial metaverse and digital twins are, here’s a look at four recommended application scenarios. Understanding these scenarios gives you a better idea of what the industrial metaverse provides and how it’s applied.

| Prescribing | 3D visualization |

|---|---|

|

Data scientists and system engineers create models to predict or simulate the behavior of a physical asset or process. The organization or your other engineers use these models to evaluate behavior under different conditions. For instance, what would happen if the pressure rose in the pipes, or if the model predicts the failure of the compressor? Prediction or simulation models are the digital replicas of the physical counterpart because they can prove the same behavior. |

Engineers, operators, and supervisors navigate through complex industrial systems and receive instant and intuitive information. Just think about this: What if you only have spreadsheets with a bunch of tags and text about each node or asset? Or just dashboards with real-time telemetry from dozens of temperature sensors? In 3D visualization, the key outcome is information delivery and interaction with your system. |

| Collaboration | Autonomy |

|

Designers at various locations don’t need to travel, because now they meet in virtual environments. Instead of recreating physical components of your product, you apply the same design change in a matter of seconds in a virtual environment. As a result, designers and engineers deliver projects faster, with reduced materials and labor costs. |

Robotics and system engineers train robots how to avoid obstacles in a warehouse in a virtual environment before operating the real robot in a real environment. In this way, it’s less expensive, and sometimes, it’s the only way you build an advanced automation algorithm for a production line. |

Industrial metaverse and digital twin convergence

The term industrial metaverse is typically used as an umbrella that covers both digital twins and the industrial metaverse.

In real life, all four business application scenarios typically play together. To get a better idea of what the primary applications of digital twins and the industrial metaverse are, consider the following:

|

Digital twins are primarily about prescribing and 3D visualization. |

|

Conceptually, a metaverse primarily covers collaboration, leveraging Digital Twins. |

|

Autonomy is a product of both digital twins and the industrial metaverse. |

Conclusion

In the years to come, the industrial metaverse will transform your operations, elevate efficiency, and optimize your workforce.

Because of the industrial metaverse’s expected rise and game-changer status, engage with a trusted and experienced technology partner like SoftServe — a preeminent, global authority on the creation and operation of industrial metaverse applications through NVIDIA Omniverse and other enabling technologies. That way you can accelerate the adoption of the industrial metaverse and wield the power of digital transformation through achieved business goals.

Doing so accelerates your digital journey during all stages — from evaluating business value through implementing the industrial metaverse at scale to mitigating risks and converting your business initiatives into reality.

For more information and details about the uses and benefits of the digital twin, download the white paper, Demystifying the Digital Twin Process. You can also soon download the white paper, “When Digital Twins and the Industrial Metaverse Converge,” to get a deeper dive into SoftServe’s industrial metaverse and digital twin expertise and use cases.