Don't want to miss a thing?

Closing the Gaps: From Missing Features to Strategic Clarity with AI Visual Inspection

In brief

- AI-powered visual inspection helps high-mix manufacturers close gaps in defect detection, efficiency, and data visibility that manual inspection struggles with.

- It increases accuracy, speeds up inspection, and provides actionable insights for continuous process improvement.

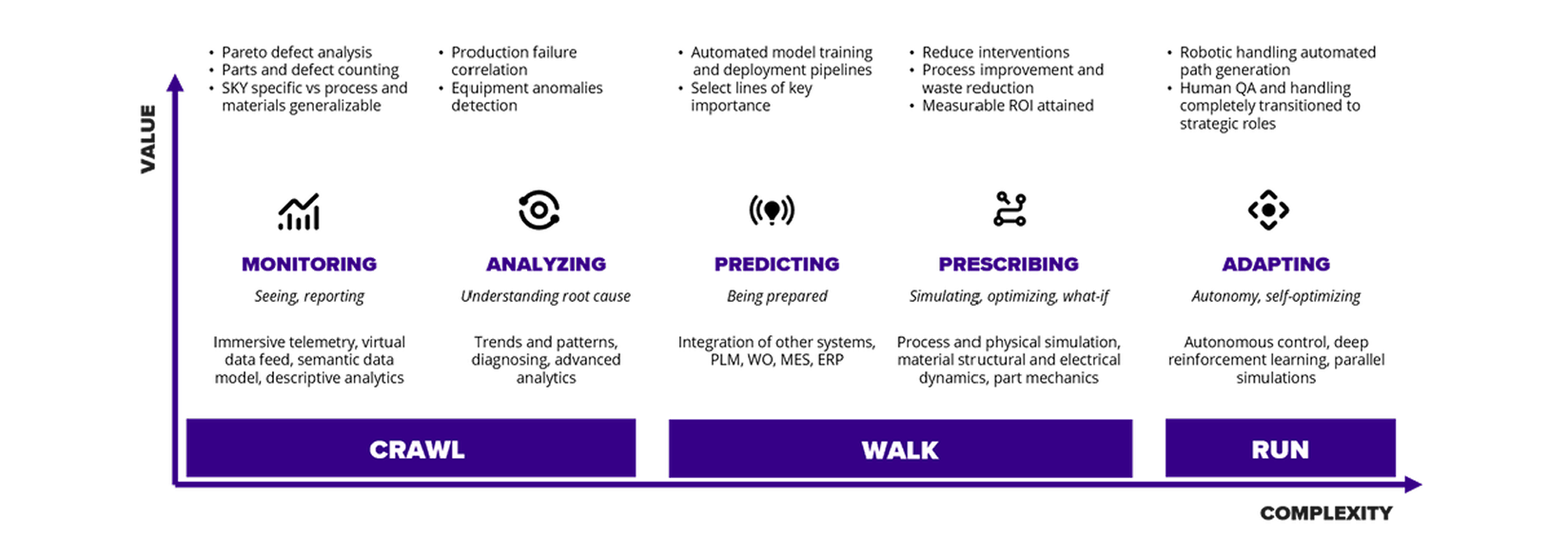

- A phased “crawl, walk, run” approach enables scalable implementation, delivering measurable ROI, higher quality, and stronger operational performance.

In high-mix manufacturing, manual visual inspections struggle to maintain consistent quality, leading to errors and delays. Humans can’t keep up with the growing number of products, rising customization demands, and the pressure for near-perfect quality.

High-mix visual inspection powered by AI is emerging as a practical way to close these gaps and strengthen quality control. By combining part-specific precision with generalized defect knowledge, AI delivers clear benefits: fewer escaped defects, measurable labor cost savings, higher throughput, and actionable insights for continuous improvement. With a phased approach that balances investment and value, AI-powered visual inspection is becoming an increasingly realistic option for manufacturers looking to stay competitive.

This article addresses the critical gaps in detection accuracy, operational efficiency, and data visibility inherent in manual processes, outlining how a crawl, walk, run approach can drive meaningful improvement.

The high-mix quality reality: where the gaps exist

Consider the seemingly minor “missing feature” defect in injection-molded parts — a result of incomplete plastic flow. This small issue highlights the larger gaps in traditional quality control for high-mix manufacturing. Relying solely on human inspection introduces vulnerabilities. The detection gap stems from the limitations of human inspectors: fatigue, subjective judgment, and the challenge of consistently spotting subtle anomalies across many parts. As a result, defects escape detection, scrap rates rise, and warranty risks increase.

Manual inspection also creates an efficiency gap. Slow, labor-intensive processes become bottlenecks, limiting throughput and scalability as product volumes and variations grow. Meeting tight production timelines and fluctuating demand becomes a constant challenge.

Equally critical is the visibility gap. Manual inspection provides limited structured data, leaving manufacturers with blind spots in defect trends, root causes, and process improvement opportunities. Valuable insights remain locked in inspectors’ experience, making them hard to capture systematically.

Together, these gaps in detection, efficiency, and visibility hinder high-mix manufacturers from achieving operational excellence and stronger ROI.

AI VISUAL INSPECTION: KEY CAPABILITIES AND PRACTICAL ADVANTAGES

AI-powered visual inspection offers a practical solution to systematically close these critical gaps and elevate quality control into a strategic asset. Here’s how AI bridges the divide:

Closing the detection gap: enhanced defect detection

AI delivers high accuracy and consistency in defect detection, surpassing human vision. Trained on large datasets of real and synthetic images, it can identify subtle anomalies such as “missing features,” small discolorations, or surface variations that humans often miss.

Using a hybrid learning approach, AI captures the unique characteristics of individual parts with CAD data and synthetic data generation tools like NVIDIA Omniverse Replicator, while also generalizing common defect patterns across materials and processes.

By storing datasets in cloud or hybrid infrastructure and training models there, AI consolidates learning from every deployment. This adaptability enables reliable SKU gap detection, identifying both individual deviations and common defects across the product portfolio. The result is fewer escaped defects and a continuously improving level of quality assurance.

Closing the efficiency gap: faster and scalable inspection

Automation drives efficiency: using edge computing like NVIDIA GPUs and NVIDIA Metropolis, AI inspects parts much faster than humans, eliminating bottlenecks and increasing throughput. This speed advantage is amplified by AI's hybrid learning models, which dramatically reduce the effort of training and deployment for each new SKU.

The scalability of AI is equally transformative. As production volumes grow and product mixes evolve, AI systems can readily adapt and scale to meet increasing demands without requiring proportional increases in labor or inspection time, effectively closing the efficiency gap that constrains manual processes.

Closing the visibility gap: data-driven insights

AI visual inspection for defect detection transforms quality control in manufacturing from a reactive process into a proactive, data-driven discipline. The system automatically captures and analyzes detailed data on every inspected part, providing actionable insights. This data includes precise defect categorization, frequency analysis (supporting Pareto charts for prioritized improvement), and even defect location mapping on parts.

By closing the visibility gap, AI empowers manufacturers to make real data-backed decisions. These insights facilitate root cause analysis, targeted process optimization, predictive quality measures, and a continuous improvement cycle that drives ongoing gains in both product quality and manufacturing efficiency.

Practical Business Advantages

- Significantly reduced escaped defects (closing the quality gap): Reduce warranty claims, improve customer satisfaction, and protect brand reputation by dramatically reducing defects that reach the market.

- Tangible labor cost savings (closing the efficiency gap): Shift skilled inspectors to higher-value work such as process optimization, complex defect analysis, and AI system supervision, maximizing human capital and reducing labor costs associated with repetitive manual tasks.

- Increased throughput and faster cycle times (closing the bottleneck gap): Accelerate production cycles, meet demanding delivery schedules, and improve overall manufacturing agility by eliminating inspection bottlenecks and enabling faster part processing.

- Actionable data for process optimization and waste reduction (closing the visibility gap): Uncover defect trends and root causes to drive data-driven process improvements, reduce scrap and rework, optimize material use, and enhance overall manufacturing efficiency.

- Improved customer satisfaction & brand reputation (closing the expectation gap): Consistently deliver higher quality products, exceed customer expectations, foster loyalty, and strengthen brand reputation in competitive markets.

PHASED ROADMAP FOR AI VISUAL INSPECTION

Implementing AI-powered visual inspection is a journey, not a flip of a switch. A phased “crawl, walk, run” approach offers a practical, low-risk path to realizing the full benefits of AI-driven quality control, systematically closing critical gaps at each stage:

- “Crawl” phase: building a robust foundation

The first phase focuses on establishing the data foundation and infrastructure. Pilot projects target specific product lines or defect types to demonstrate early wins and collect real-world data. This includes integrating CAD data, capturing initial image datasets, and using synthetic data to augment training. AI runs alongside manual inspection, supporting inspectors while refining models. The focus is on learning, developing internal expertise, gaining situational awareness, and showing the potential for gap closure while managing initial investment and operational change. - “Walk” phase: validating performance and efficiency

The “walk” phase involves validation and optimization. AI and manual inspection lines continue to operate in parallel, but now with a focus on benchmarking performance metrics — defect detection rates, accuracy, and throughput. This phase is critical for fine-tuning AI models, optimizing system parameters, and building confidence in AI’s ability to close the detection and efficiency gaps. Early efficiency gains become more apparent as AI takes on a greater share of the inspection workload, and data-driven process improvements begin to yield tangible results. - “Run” phase: scaling for portfolio-wide impact

In the “run” phase, AI visual inspection becomes the main quality control method, scaling across product portfolios and manufacturing processes. Its hybrid learning capabilities enable efficient, robust inspection across diverse SKUs and defect types. Human inspectors shift to strategic roles, overseeing AI performance, analyzing complex defects, and driving continuous process improvements. This phase delivers sustainable ROI, systematically closing quality, efficiency, and visibility gaps, and fostering a data-driven culture of manufacturing excellence. Full-scale deployment also unlocks AI’s ability to generalize defect knowledge across the entire high-mix operation, including support for robotic automation.

Strategic clarity: achieving manufacturing excellency

Moving beyond manual inspection isn’t just about catching isolated defects; it’s about achieving strategic clarity in quality control. AI visual inspection provides a comprehensive, data-driven view of the entire manufacturing process, empowering leaders to make informed decisions, optimize operations proactively, and drive continuous improvement.

With a phased implementation approach, AI-powered visual inspection delivers measurable ROI, improves customer satisfaction, and establishes a sustainable competitive advantage in today’s high-mix manufacturing environment.

To explore how it can support your operations, contact SoftServe. We provide end-to-end guidance and implementation support.