Don't want to miss a thing?

Robotics and Physical AI In Oil & Gas: The Path to Autonomous Operations

In brief

- The energy industry faces profound challenges like aging infrastructure, downtime, and safety risks that require smarter solutions.

- Robotics and Physical AI in oil and gas enhance operations by increasing efficiency, lowering costs, and improving safety.

- SoftServe’s simulation-first approach enables energy leaders to adopt robotics confidently and achieve complete asset visibility.

Leaders in the oil & gas industry understand the immense challenges they face. Aging infrastructure and unplanned downtime put productivity and safety at risk. Corrosion, leaks, and structural fatigue often go unnoticed until they lead to costly failures. Fragmented data makes it harder to act quickly.

To address these challenges, organizations need more intelligent and secure operations supported by ongoing process intelligence. Robotics and Physical AI aren’t just innovative; they’re essential for addressing today’s risks and building resilient systems.

In this article, you’ll discover how to remove bottlenecks, achieve total asset visibility, and scale robotics confidently with SoftServe’s simulation-first approach.

Deploy Robotics to Remove Critical Bottlenecks

The value of switching to robotic inspection isn't theoretical. The data shows a clear advantage in efficiency and safety.

How Robotics Drives Efficiency in Energy

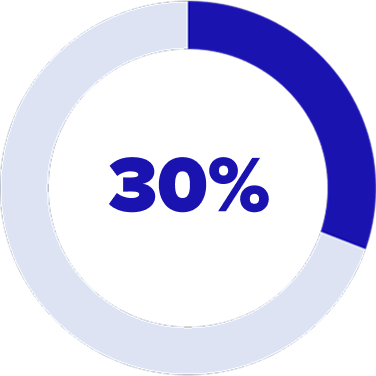

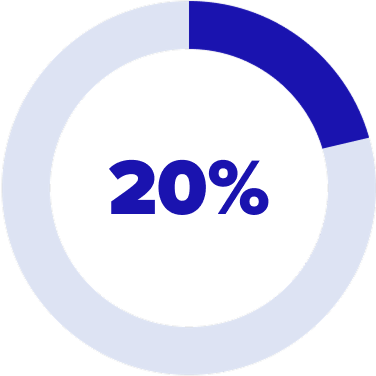

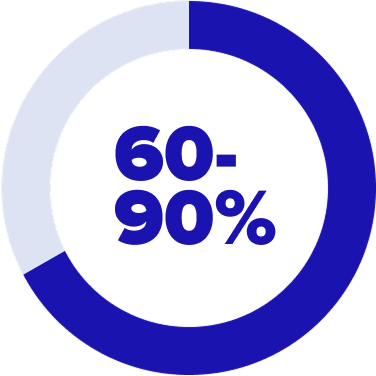

A study in Applied Sciences shows autonomous robots complete routines 30% faster than manual workflows. The 2025 Remote Inspections and Operations Special Report highlights that automation cuts over 20% of manual effort, freeing your skilled engineers for high-value tasks. Robotics also nearly eliminates confined-space exposures and reduces work-at-height risks by 60–90%, according to Rigzone.

Beyond safety, the financial argument is compelling. When paired with Physical AI, robotics can reduce potential operating costs.

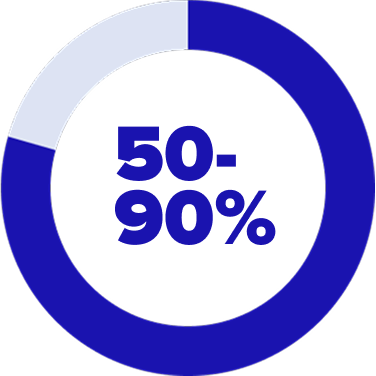

The Cost-Saving Power of Robotics

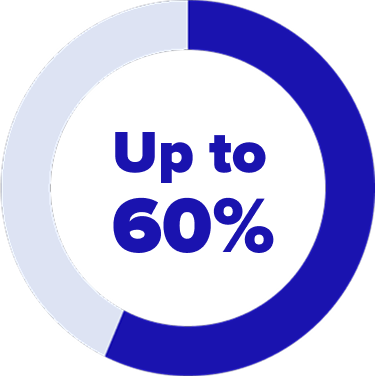

Inspection costs drop by 50–90% when replacing rope access teams and heavy scaffolding with autonomous systems. Tank inspection costs decrease by 30–60% using in-service robots, as highlighted in the same Rigzone report.

To fully realize these economic and operational benefits, organizations must expand robotics beyond isolated tasks and toward a unified, multi-domain strategy.

Build a Multi-Domain Robotics Architecture

A common mistake is treating robotics as a niche solution for a single problem. From the North Sea to offshore fields across the Atlantic, autonomous units are performing tasks that were once deemed too complex for machines. These advances are fundamentally changing how operators monitor, inspect, and maintain assets.

Facing challenges with emissions, efficiency, or safety in your energy operations?

Discover practical solutions to your challenges. Read moreOnshore Operations

Onshore, vast distances and invisible threats make monitoring a challenge. To overcome this, drones and unmanned ground vehicles (UGVs) patrol pipeline networks and tank farms, using gas detection, thermal imaging, and visual data to quickly pinpoint issues like methane leaks or corrosion. This rapid detection helps you address problems before they escalate into environmental or safety crises.

Offshore Topsides

Offshore platforms present a unique challenge: their verticality and confinement make many tasks hazardous for humans. The application of robotics in the offshore oil and gas industry has advanced the execution of these tasks. Legged and wheeled robots navigate grated stairs and slippery decks to perform confined-space entries. When powered by physics-driven simulations, they can detect leaks and structural fatigue with a consistency that human inspection simply cannot match. This reduces the need for personnel to enter hazardous zones, directly lowering the risk of injury.

Subsea Intervention

Below the waterline, the stakes are even higher. Traditional inspection requires expensive vessel support and divers. Autonomous Underwater Vehicles (AUVs) and Remotely Operated Vehicles (ROVs) are inspecting pipelines and valves using sonar and laser scanning. This technology enables predictive maintenance in oil and gas from the deep, identifying issues like seabed shifting or pipeline fatigue without putting a diver in the water. By moving to autonomous subsea inspection, you cut costs associated with support vessels.

Emergency Response

When a crisis hits, seconds matter, but human intervention is often too dangerous. Rapid-deploy systems conduct hazard assessment and safely intervene where humans cannot. This capability provides critical situational awareness during emergencies, allowing for informed decision-making without endangering lives.

Simulate First, Scale with Twins

Every autonomous system must prove its safety and reliability before entering live operations. SoftServe enables rapid, confident robotics adoption through a simulation-first automation lifecycle.

Using NVIDIA Omniverse™, Isaac Sim™, and preCICE™, SoftServe models fluid dynamics, material stress, sensor behavior, and multi-robot interactions. This ensures offshore and subsea robots are prepared to operate safely and predictably in extreme, high-risk environments.

This simulation-first approach offers three distinct advantages:

This simulation capability evolves into the control layer of your operations: the digital twin.

Built on NVIDIA Omniverse™ and PhysicsNeMo™, SoftServe delivers simulation-first, physics-informed digital twins that integrate real-time data, robotics, and AI. Once deployed, industrial digital twins provide continuously synchronized virtual replicas of onshore facilities, offshore platforms, pipelines, and subsea infrastructure.

As real-world robotic and sensor data feeds back into the twin, operators can:

- Detect faults early and perform predictive maintenance in oil and gas.

- Optimize inspection routes and workflows.

- Make safer, data-driven operational decisions

Simulation-first development and industrial digital twins work together to create a feedback loop. This approach de-risks deployment upfront and improves performance over time.

Operationalize Robotics Through Unified Orchestration

Buying a robot is easy. Getting value from a fleet of robots requires orchestration. True autonomy moves beyond isolated pilots and connects the robotic workforce directly with the existing infrastructure, such as SCADA and Distributed Control Systems (DCS).

When robotics, simulation environments, digital twins, and control systems are unified, autonomous systems evolve from isolated tools into a high-performance operations engine.

The Benefits of Orchestration

- Gain Real-Time Situational Awareness: Instead of waiting for a report, operators get live visibility into asset health, robot performance, and environmental data across onshore, offshore, and subsea operations.

- Create Seamless Hardware–Software Integration: Orchestration creates a continuous data pipeline connecting robots, sensors, and actuators. The data doesn't sit on the robot; it flows instantly to the people who need to make decisions.

- Achieve Enterprise-Grade Connectivity: Direct integration with SCADA/DCS and asset systems aligns robotics with existing workflows and predictive maintenance strategies.

- Enable Coordinated Multi-Robot Operations: This allows centralized task allocation. The robotic fleet operates as a single, cohesive system, prioritizing tasks based on real-time operational needs rather than rigid schedules.

Accelerate Adoption with a Clear Maturity Path

Advancing your operations doesn't happen overnight. It requires a roadmap to resilience that scales with confidence.

This approach ensures your systems are ready to build resilient, efficient operations and meet future challenges with confidence.

Learn more about how essential robotic process automation is in the oil and gas industry.

Explore real-world examples, such as pipeline inspections and predictive maintenance, that reduce risks and costs.

Download our white paper on Physical AI-Driven Robotics for Oil & Gas Get your copyYour challenges need innovative solutions. SoftServe’s robotics and simulations make oil and gas operations safer and more efficient. Talk to us to turn obstacles into opportunities with robotics and Physical AI.

Start a conversation with us